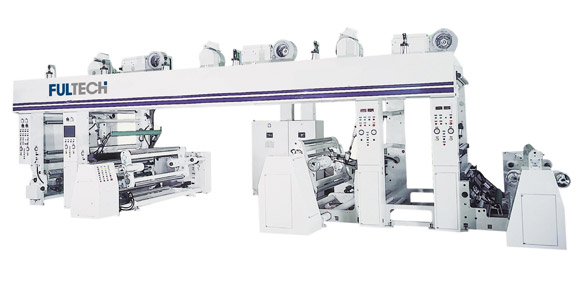

| 1. This series of laminators is designed for great production efficiency at a lower investment level. The machine is very easy to operate and can be easily used by those with printing machine operation skills. |

| 2. Tension problems during the laminating process are eliminated by use of the micro location offset via dancing roller control systems, which allow for foil (6 micron) to laminate with other various films. It provides the most stable tension even the material has passed through the dryer and been affected by the temperature. |

3. The synchronized motion of the laminating and gluing devices is of a non-shaft design which fully eliminates accumulated tolerance and facilitates the movement of both semi- and fully-completed products.

|

4. Laminating unit equipped with 10.4 colorful touch screen and PLC controller.

The operation parameters such as unwind tension, rewind tension, temperature, motors speed are setting digitally. Machine auto stop functions when material run out or break. All values setting and displaying are clear for ease of operation.

|

5. Gluing unit also equipped with LCD touch screen. It is convenient for machine pre-run settings such as glue adjustment, hot melt temperature, doctor blade movement and gravure coating roller clean device.

|

| |